CM1 MONITOR

High Capacity Shredder Tracker

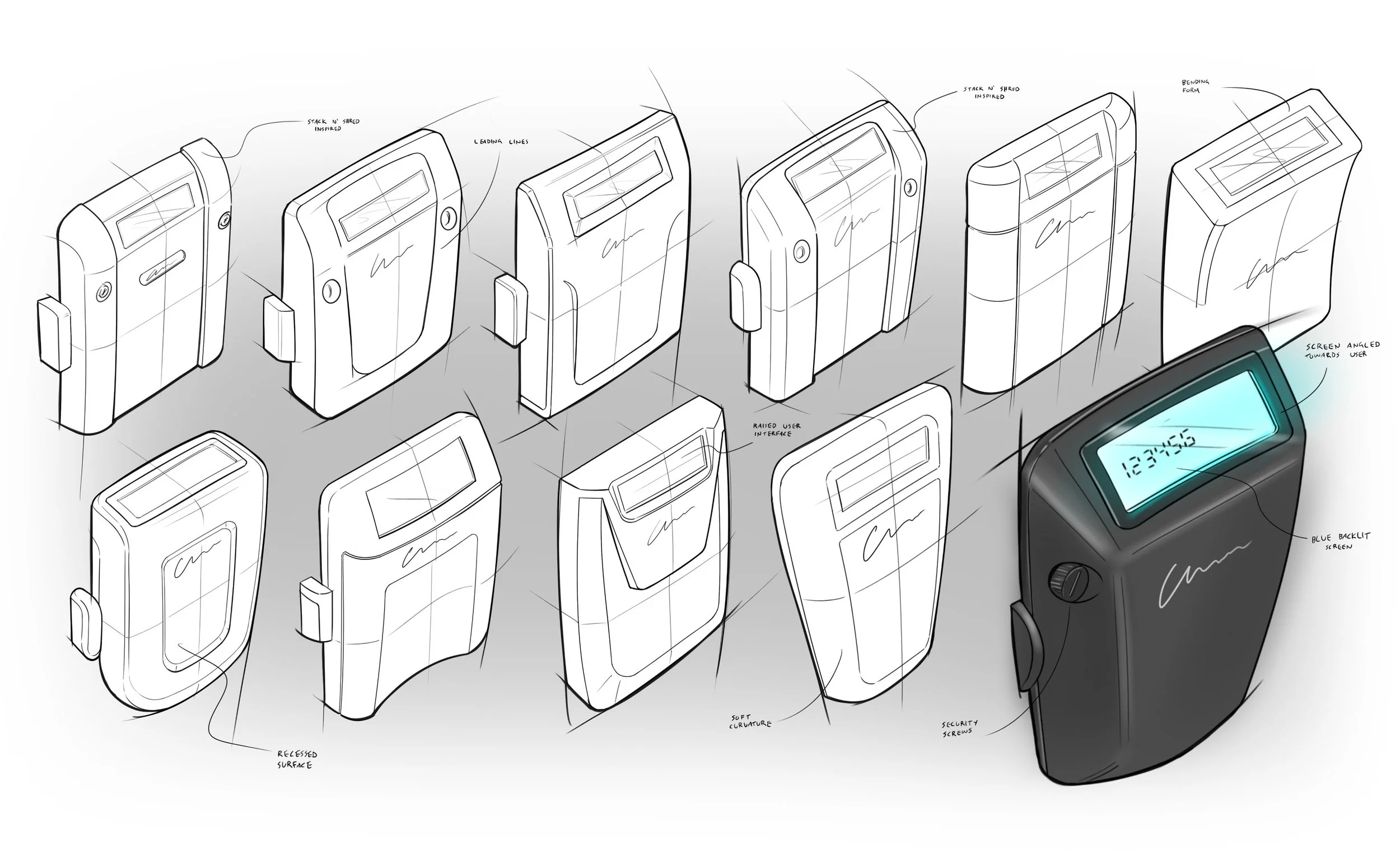

In large corporate environments, high-capacity shredders are often leased for secure document disposal. As part of this service, a monitoring system is used to track and record shredding activity. The primary design objective for this project was to develop a protective housing for the monitoring unit. This project focused on form exploration and design refinement for the tracking module, while remaining functional, secure, and easy to integrate into existing shredder models.

I explored the possibilities of how surface design can serve multiple roles—creating visual interest, providing functional benefits, and offering tactile cues that guide user interaction. This exploration included looking at how curvature could influence the way users perceive and engage with a product. By exploring how curvature is used, I was able to test different forms and utilize visual and directional cues.

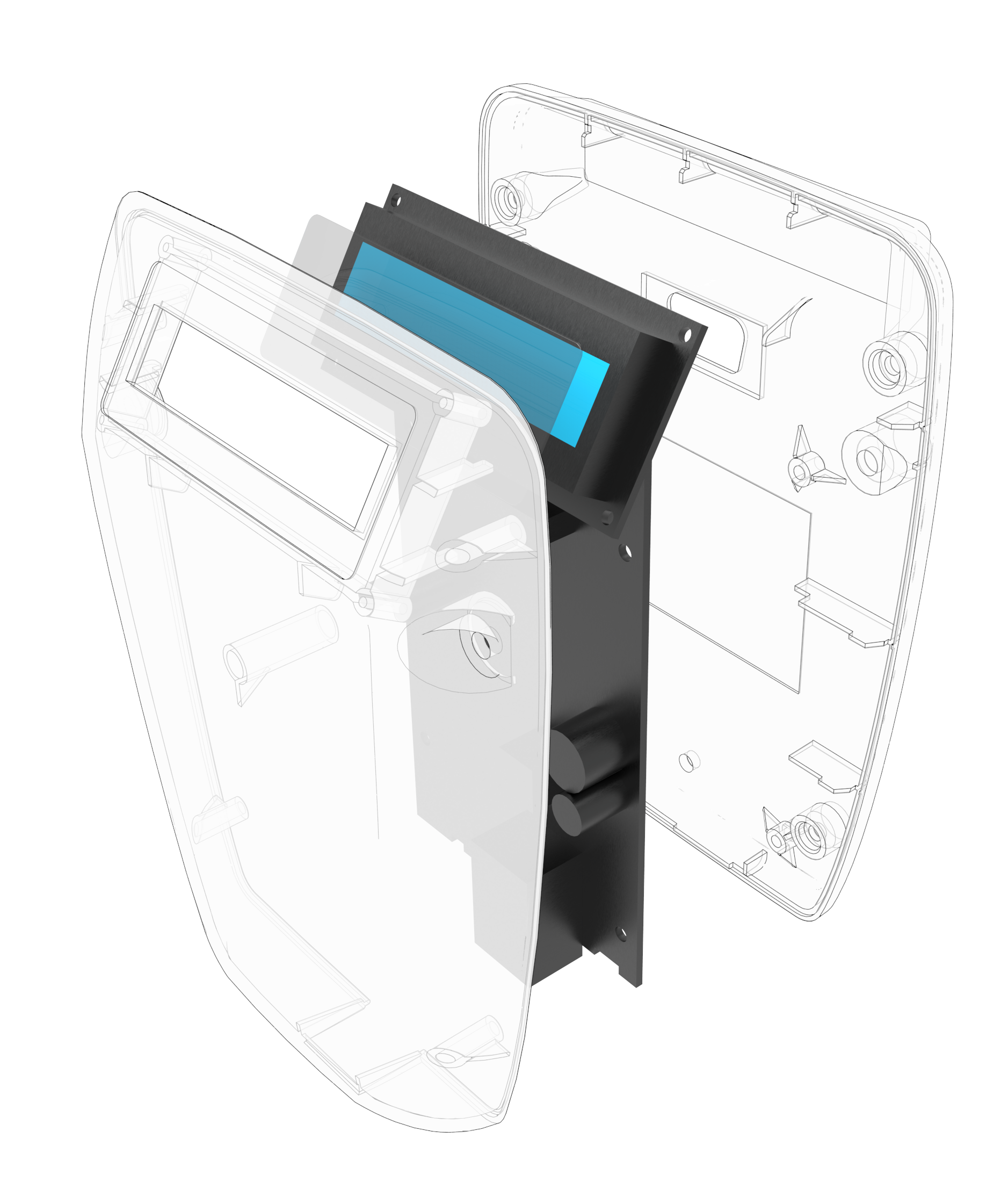

manufacturability + part design

This project began as an aesthetic exercise, but designing for manufacturability remained a key priority throughout. I developed the external housing with careful consideration for injection molding. I optimized the design to support internal electronics, mounting ribs, and fastener locations. Overall, the exploration offered valuable insights into material strength and efficient tooling design.

SHRED.

ACCO Brand high capacity shredders are leased out to organizations

TRACK.

The CMI Tracking monitor is connected at the rear of the shredding unit using a VGA connection and LAN cable Port on Base

MONITOR.

A off-site technician monitors and trackers shredders use